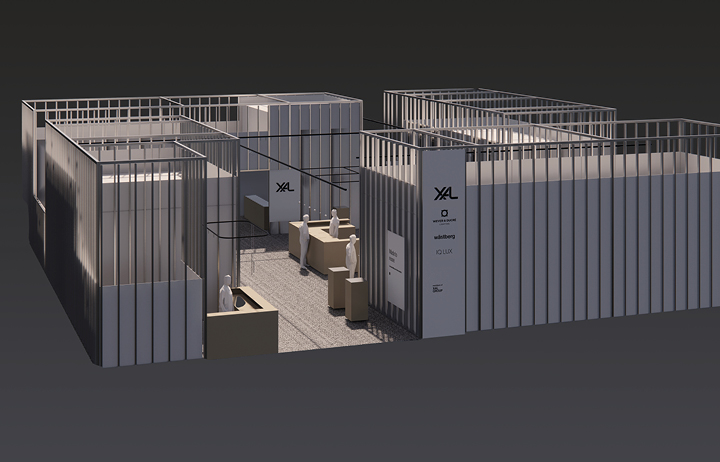

made to reuse

Our booth this year surprises with a minimalist backdrop. Behind it lies a stand concept built on longevity. The driving force? Our environment. To make our trade show appearance as sustainable as possible, we collaborated across departments to devise solutions that are resource-efficient and durable for future uses. We’ve unearthed old treasures and combined them with new elements that are not only modular and practical but also highlight the natural beauty of raw materials. The best part is that the components of our booth are already part of future projects.

The shell

-1,4 tonnes CO₂ eq

Our booth is deliberately encased in drywall panels. 1,000m² were installed. The panels are not filled and, as far as possible, not cut to size. This means that the panels remain intact and nothing stands in the way of a second use. To minimise transport distances, our supplier transported the 10 tonnes drywall panels directly 23km to the exhibition hall. Compared to delivery from Graz, this saves 628kg CO₂ eq. After the trade fair, the boards are reused in the extension of the XAL headquarters. The drywall panels used have a footprint of 1.4kg CO₂ eq/m². The avoided impact outside the system boundaries through the reuse of the panels is therefore 1.4 tonnes of CO₂ eq for the 1,000m².

Crates / furniture

-44% transport volume

Reusing the transport crates of our exhibited products as furniture at the trade show allows us to reduce the transport volume of the furniture by 44%. This calculation assumed that without using the transport crates as furniture pieces, the furniture would be additionally shipped in the size of the transport crates.

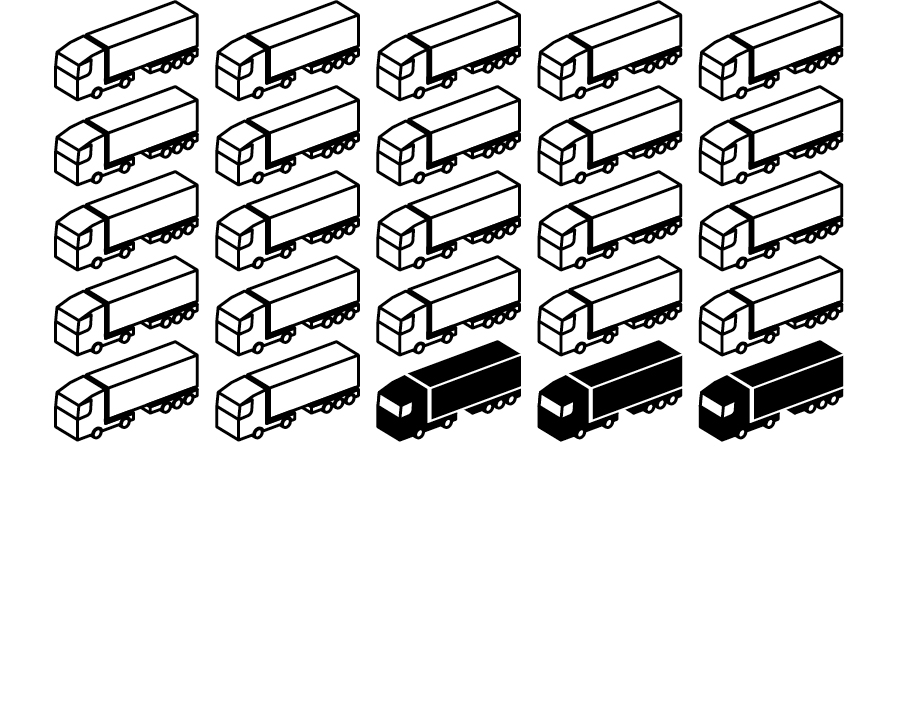

Transport

-22,3 tonnes CO₂ eq

Compared to XAL’s participation in the trade show in 2018, this year 3 instead of 25 trucks drove from Graz to Frankfurt. For the return trip, 1 additional truck is included for the reused drywall panels. The distance from Graz to Frankfurt is 730km, and it was assumed that each truck carries 8 tonnes. Using the average emission factor for trucks provided by the Austrian Environment Agency (as of July 2023), we calculated a total reduction of 22.3t CO₂ eq from truck transports.

Kitchen/Bar/Furniture

Reuse instead of recycling

Reusing already produced, functional furniture pieces is even more sustainable than recycling, as the energy expenditure is usually lower. That’s why we are using our kitchen from previous trade shows again. The bar is modular and designed for simple transport, and the seating furniture is made from undyed, interlocking recycled cardboard, allowing the bar and furniture to be used for various events in the future. Additionally, other existing furniture from past trade shows is reused at the booth.

The carpet

A second life

If you ever set foot in the building under construction in Graz, you will likely step on the carpet that was laid at our booth. By predetermining reuse in the expanded Headquarters, we focused on an optimized order to dispose of almost no carpet remnants at the trade show. Just like the drywall panels, the carpet will also be reused in Graz. The unique aspect of Object Carpet’s circular product is that after its life as a carpet, it can serve as raw material for 3D printing.

Today,

tomorrow

and in

future

Today, tomorrow and in future

As a business, we perceive our role within a wider context of humanity and environment, to which we are committed – for the present day and for a future worth living. For us, corporate, social and environmental responsibility are equally important and go hand-in-hand, which is why sustainability is anchored as a basic principle of our actions at all organisational levels.

In case you have any questions regarding the environmental performance of our products, feel free to get it touch at sustainability@xal.com

Glossar

Footprint – is the value for GWP (total). GWP stands for Global Warming Potential and is measured in the unit CO₂ equivalents. This value allows comparison between different products and their environmental impact.

Source for Reuse calculation: Etienne et al 2022 IOP Conf. Ser.: Earth Environ. Sci. 1078 012015

Details on the values

The shell

The manufacturer of the panels provides an EPD and therefore values for the carbon footprint per m². We look at the use at the fair and the use in the building in Graz as different systems. Calculating the reuse according to Etienne et al, we consider the reused materials leaving the system secondary materials. The input flow of secondary materials for this system (the use of the drywall panels at the booth) is zero. The avoided impact, due to the reuse, is the impact of the production of the drywall panels minus the impact of the processes required to prepare the product for reuse. In our case no processes are required to prepare the product for reuse, therefore the avoided impact outside the system boundaries equals the impact from production. In other words, from a technical point of view the reduction of emissions for the dry wall happens at the construction site in Graz, not at the fair.

Details on the values

The carpet

The manufacturer of the carpet provides EPDs for two products, similar to the one used. This allows to assume, that the highest impact comes from the production of the carpet. We look at the use at the fair and the use in the building in Graz as different systems. Following the proposed calculation method for reuse of materials by Etienne et al, credits for reuse are counted as credits outside the system boundaries. Therefore, the benefits from reuse become significant in the system following the use at the fair as secondary material input.

The values have not been verified externally.